Loading...

Knowledge Base

Loading...

HOW TO CHECK THAT YOUR COOLANT IS IN GOOD CONDITION

How far do you have to go to get your coolant conditions right?

Loading...

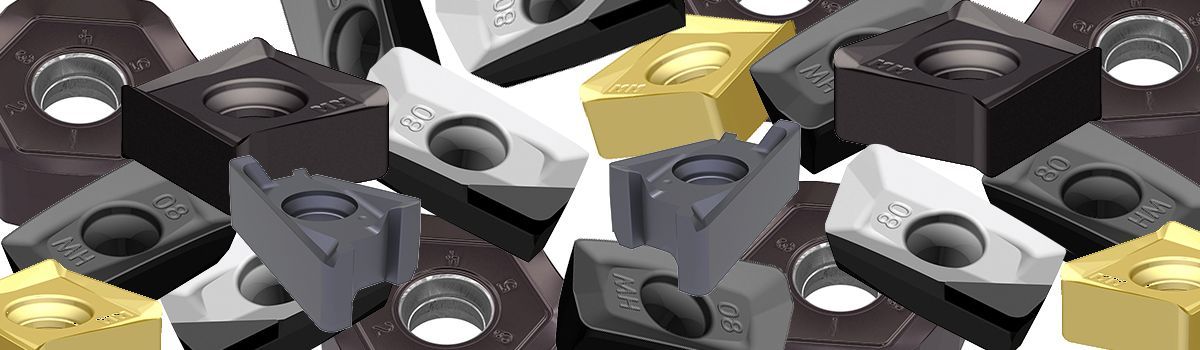

UNDERSTANDING OUR GRADES AND GEOMETRIES

Want to have a better understanding of range of milling inserts? then look no further.

Loading...

STREAMLINE YOUR MAGDRILLING

Many machines are only single-speed or two-speed, better machines have variable speed control, read this article to learn more.

Loading...

PUNCH AND DIES

Primarily used in fabrication operations to cut out components from sheet materials, punch and die sets consist of multiple punches and corresponding dies in various sizes. To see the specs and order form just click the button below.

Loading...

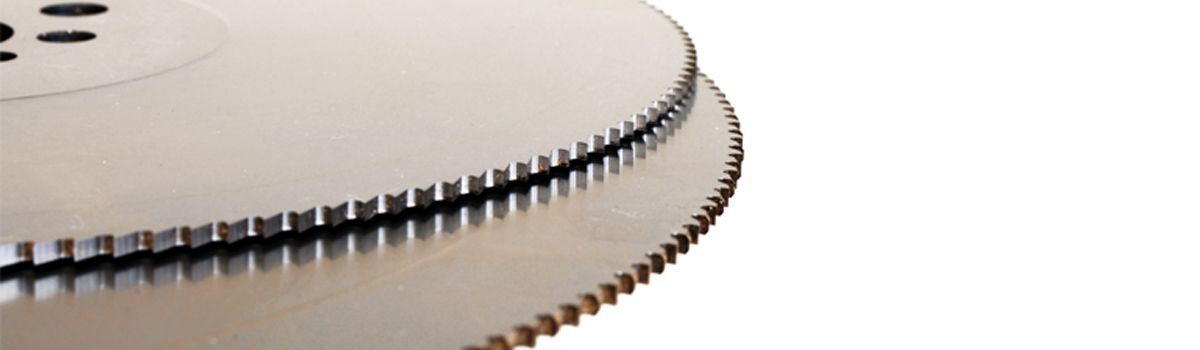

COLDSAW RUNNING SPEEDS AND ADVICE

A bit like tyres, coldsaw blades are pretty much black and round, right? Well, yes and no.