Soluble coolant concentrate needs to be mixed with water to create the cutting fluid you need. This simple step is often taken for granted by many users, but modern coolants are technical products that deserve a little more than just a hosepipe in a bucket.

A properly mixed batch of cutting fluid will give the best performance and be more resistant to infection and degradation, lasting longer in the sump and providing better ROI.

Following this simple checklist will ensure you get your cutting fluid off to the best start.

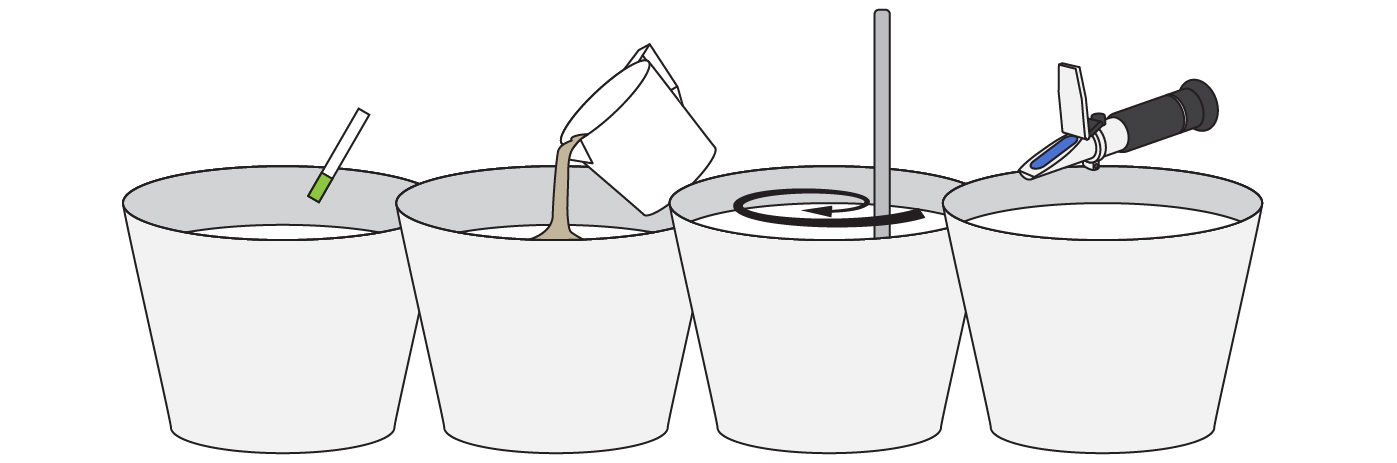

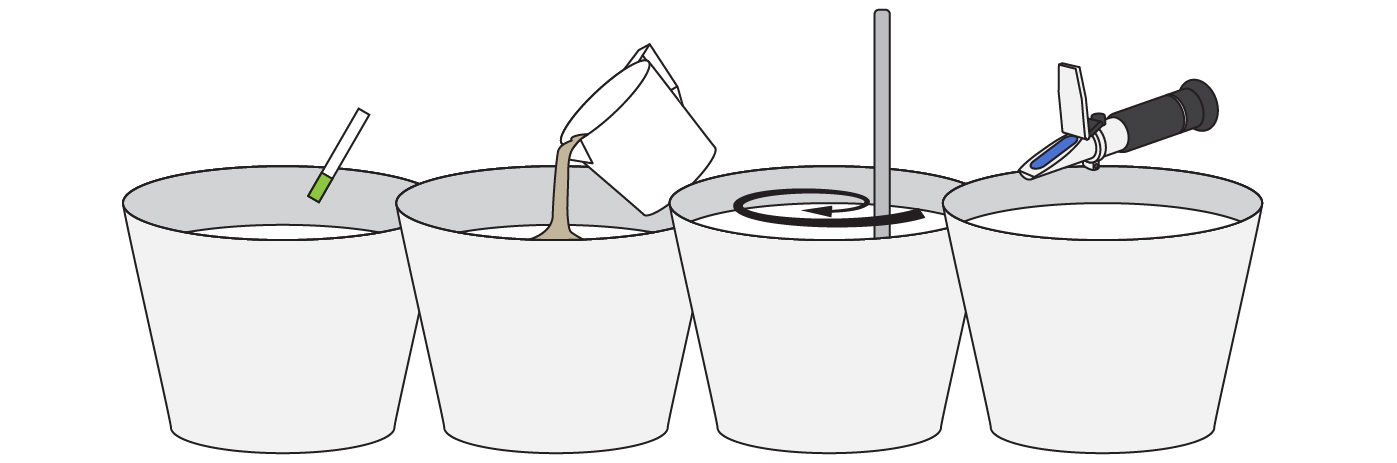

- Start by testing and recording the pH of your water supply, it will provide a useful reference for monitoring the health of your cutting fluid and could help you catch infections before they ruin your coolant.

- Always use a clean, separate container to prepare the emulsion in. Fill it with water first, then add the coolant at the required dilution ratio (always add the oil to the water, adding water to the oil will result in a substandard emulsion).

- Stir the mixture thoroughly and add it to the machine or system sump.

- Repeat the mixing and adding operation until the sump is half full.

- Check the dilution ratio in the sump with a refractometer (for help on using a refractometer, see our article HERE) and if the reading indicates the correct ratio, continue filling with the same mix ratio.

- If the refractometer reading shows an incorrect ratio, adjust the dilution of the remaining mixes accordingly, remembering to always mix thoroughly before adding to the sump.

- If you have made adjustments to the ratio, check the sump again at three-quarters full and re-adjust the ratio for the remaining mixes if necessary.

- Once the sump is full, take a final refractometer reading to confirm that the sump dilution ratio is correct.

You are now ready to start working with your new batch of cutting fluid.

If you would like to know more about how soluble coolants produce emulsion and how they can break down, we have a short article that explains this HERE.