The easiest way to check the dilution ratio and condition of your coolant is to use a refractometer.

A simple optical model will allow you to quickly check the dilution ratio of your coolant and will also indicate the general health of the emulsion.

Click the titles below to see more about each topic.

Before using your refractometer for the first time, you should calibrate it so that your water supply is the ‘zero point’. Calibration should be checked and adjusted from time to time to ensure the readings are accurate.

To calibrate an optical refractometer:

- Clean the prism window with a soft cloth

- Place a few drops of your water supply onto the prism window and close the daylight plate

- Check that the sample is free from bubbles, dust and contamination

- Point the refractometer towards a light source and take a reading

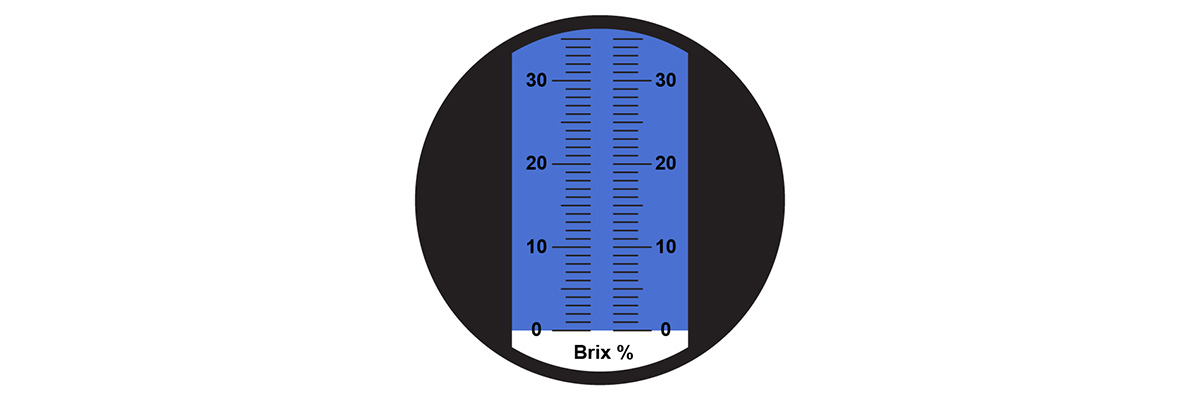

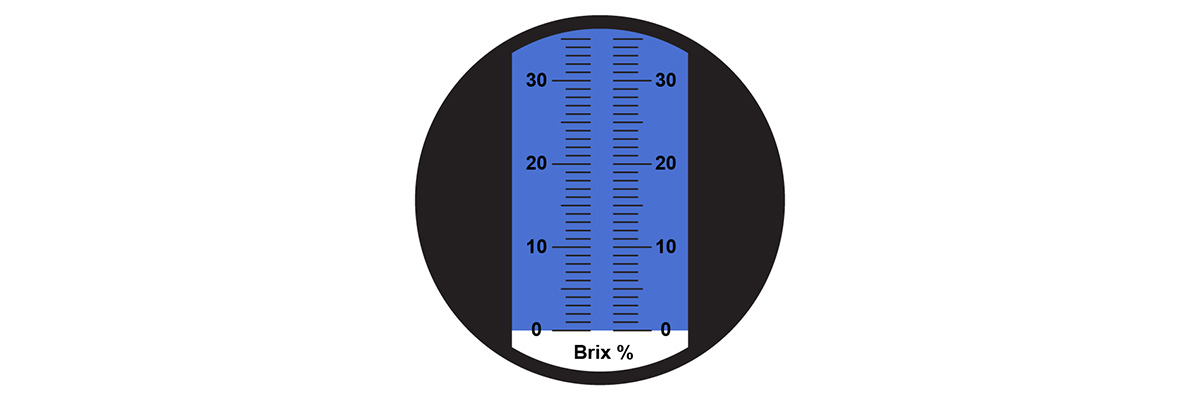

- If the reading is zero, your device is calibrated

- If the reading is NOT zero, adjust the device using the calibration screw until he reading shows zero

- Open the daylight plate and clean & dry the plate and window

Your refractometer is now ready to use with your cutting fluid mixture

Before taking the reading, make sure you have the refractometer index (R.I.) for your cutting fluid concentrate to hand, e.g Altdorf Arctic 420 =1.78 (the refractometer factor is usually found on the product label, ask your supplier if not shown)

- Ensure the prism window is clean and dry

- Place a few drops of your coolant emulsion onto the prism window and close the daylight plate

- Check that the sample is free from bubbles, dust and contamination

- Point the refractometer towards a light source and take a reading

- Multiply the reading value by the refractometer index given for your cutting fluid concentrate (e.g. refractometer reading = 7.50 : Altdorf Arctic 420 R.I. = 1.78 : actual concentration percentage = 13.35%)

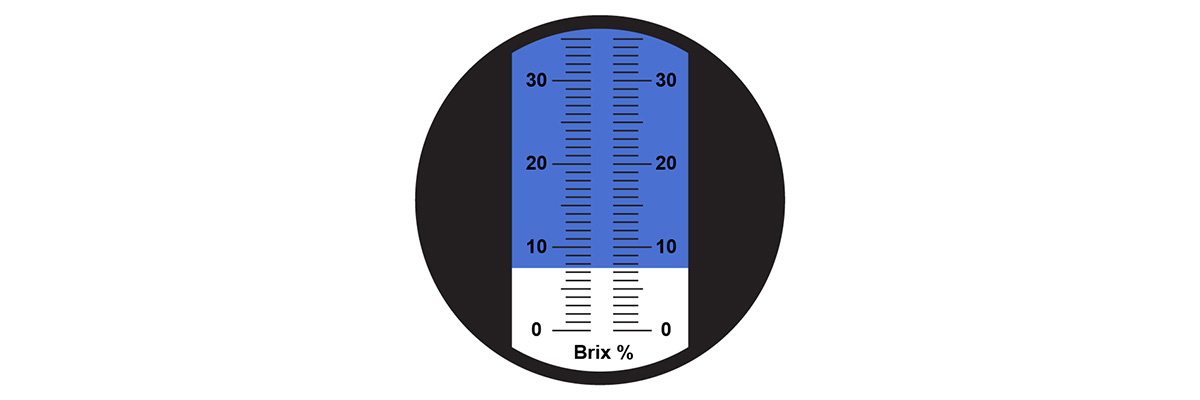

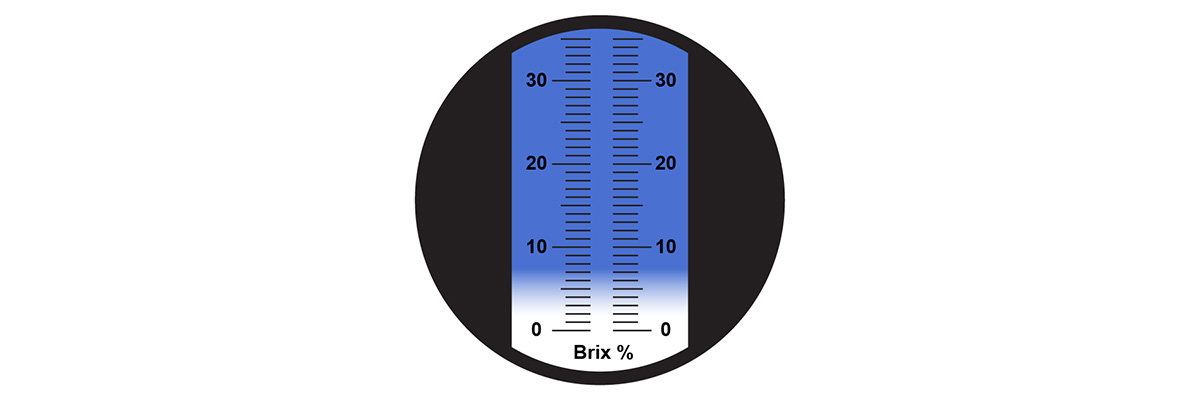

The crispness of the refractometer’s dividing line indicates the general condition of your coolant.

A sharp, clear line shows that the emulsion is consistent, meaning that the mix is fresh and free from significant contamination. Note that if your tramp oil has leaked into your coolant, you should use a slightly lower refractometer index to get a more accurate reading.

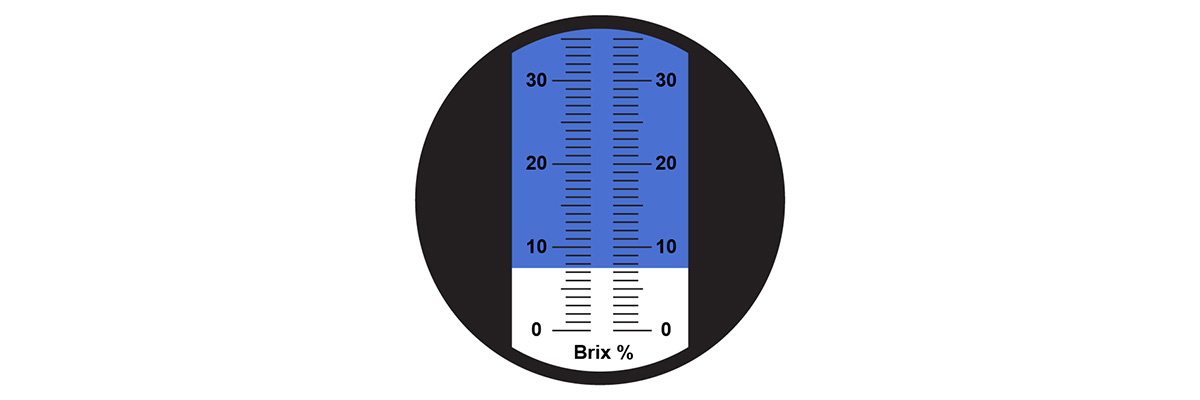

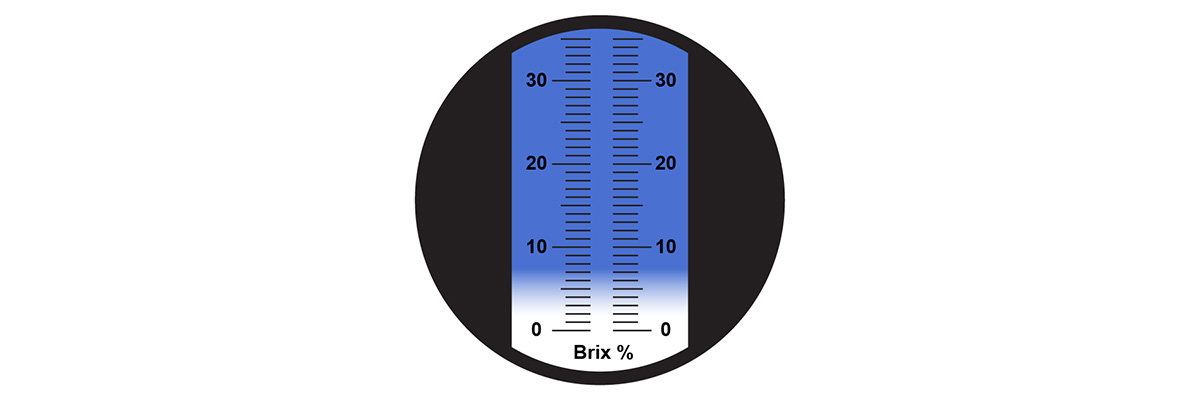

As the emulsion gets less consistent, through the reduction in available emulsifier molecules or through contamination from tramp oil and other inclusions, the line gets less distinct (although in the early stages this may be difficult to see).

If the line appears obviously fuzzy or blurred, you should change your coolant as it will be providing reduced protection and performance.

Always ensure the refractometer's prism window is clean, dry and free from oil or other chemicals prior to storing it between uses.

Your cutting fluid is a vital workshop asset, ensuring it’s always in good condition is well worth the time spent testing and monitoring with benefits in tool life, process cycle times, machine downtime, OSH concerns & staff health.

Refractometers are cheap and easy to use and regular testing will allow you to monitor the health and effectiveness of your cutting fluid.

Using cutting fluid that is past its best is the equivalent to using a blade with all the teeth missing – you might make it through the job with it but the result won’t be good and it will probably lose you money.