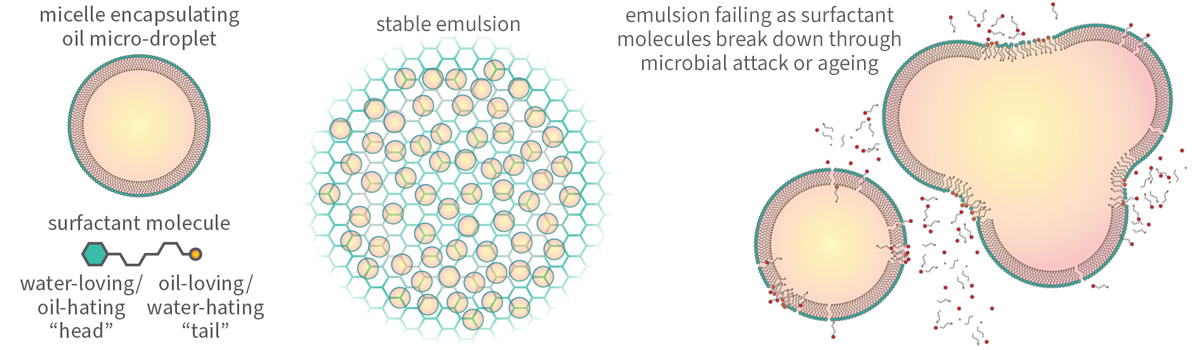

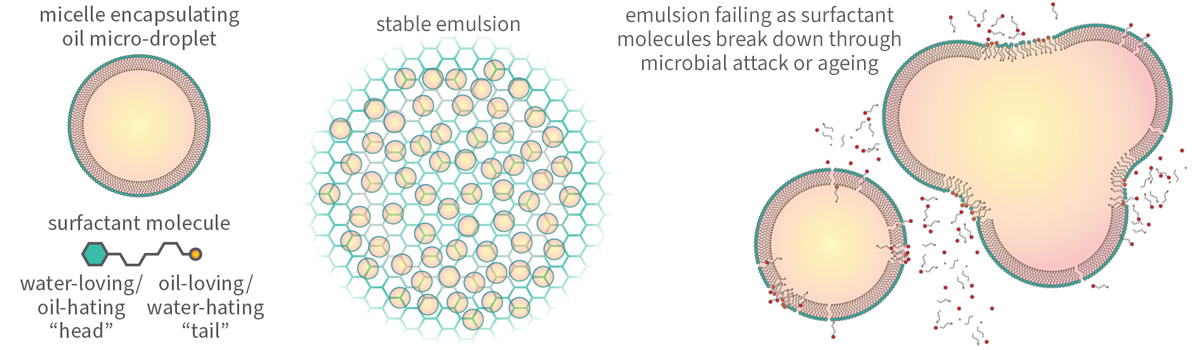

To understand what makes an emulsion break down, we need to know a little about how they are created.

Oil does not readily dissolve in water, instead it is held in suspension in an evenly distributed matrix of tiny droplets within the water. For the droplets to be small enough, and to stop them from re-joining each other and separating the water and oil back into two liquids, they rely on emulsifiers to create and control them.

Click the titles below to see more about each topic.

Emulsifiers are surfactant molecules that are attracted to water & repel oil at one end while doing the opposite at the other end. They form a spherical barrier around the oil droplet (known as a micelle) and also repel other surfactants when approached end-on, stopping droplets combining maintaining the emulsion.

They fail because the chemicals get used up. Those clever little surfactant molecules are fundamental additives in a “soluble” cutting fluid (better described as an emulsion-forming cutting fluid) but they are also a very good nutrient source for bacteria, so they are under constant attack from environmental and introduced microbes. As the bacteria feed and reproduce, they break down the emulsifier molecules, allowing some oil to escape from their surrounding barriers. This oil is either recaptured by other unused emulsifier molecules, combined with another existing micelle (if there are enough emulsifier molecules available) or remains out of the emulsion and collects at the surface or in other parts of the system.

The truth is, you can’t stop it, its an unavoidable process and the best you can do is to look after your cutting fluid during storage and use, trying to slow down the depletion of the emulsifiers and maximise the cutting fluid's effective working life. THIS ARTICLE gives more information on what steps you can take to get the best sump life from your emulsion.

Your cutting fluid is a consumable item. The additives and chemicals it contains are often intended to be used up during the working life of the product, many are being consumed even while it is not in use, including while you store it.

Knowing that you cannot avoid the changes happening in the fluid lets you focus instead on looking after it while you have it in your sump. Keep your cutting fluid within the desired range for pH and concentration to maximise the usable life (and the all-important Return on Investment) of this valuable asset.