A bit like tyres, coldsaw blades are pretty much black and round, right?

Well, yes and no. There’s a surprising amount of technical stuff behind that plain face and if you want to get the maximum value from these tools, it pays to take some time to understand them.

Click the titles below to see more about each topic.

Why the name?

The name really does say it all – these tools are meant to stay cool and to avoid excess heat buildup in the workpiece too. They manage to do this by ensuring the heat from the cutting process is transferred to the chips, so running them as intended will keep them cutting better, cooler and longer.

But, because the term “coldsaw” (or “cold saw”) is not universally applied to mean the same thing, it can still be confusing. When we say “coldsaw” (or “cold saw) we mean the simple, hollow-ground discs with ground teeth used in slow-turning dropsaw-type machines requiring a stable base, not other dropsaw-style machines used on site or carried around from one job to another and definitely not any blade with carbide teeth.

Blade types

There are different types of blade, almost all are made from DM05 HSS or Cobalt Steel and feature a hollow-ground cross-section that provides relief clearance in the cut, avoiding possible friction and heat build-up. Many are finished with a simple black steam-vapo treatment that provides a matt surface for the essential coolant to cling to and spread, others may have a coating (typically TiN or TiAlN) applied to the sides of the blade to reduce friction by adding ‘slipperiness’, although they still need to be used with a cutting fluid or other coolant. Also, their coatings tend to only provide the best benefits when used with harder materials, so they are an expensive alternative when used with softer steels.

Almost all machines in NZ will have a 32mm or 40mm bore and most blades will have a hole pattern to match the machines that use the bore of the blade.

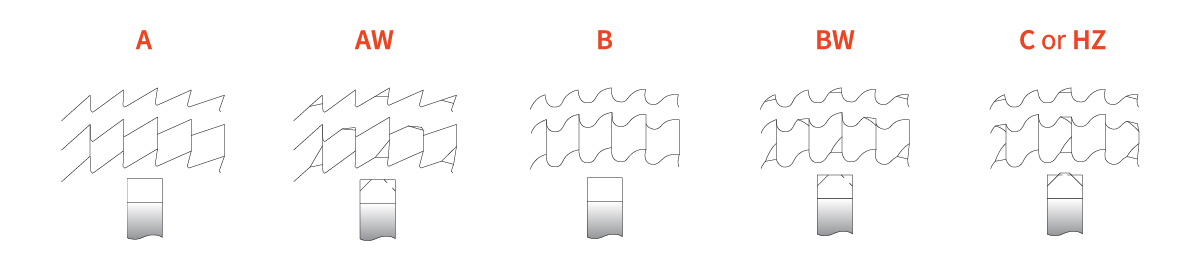

Tooth profiles

An important consideration with coldsaw blades, although one that’s often overlooked even by suppliers, is the type of tooth ground onto the blades. There are ‘general-purpose’ options (which will suit the majority of users and is why some suppliers just ignore this question) but there are other better-suited profiles for certain applications that can be beneficial for users where the ‘standard’ profile does not give the desired results.

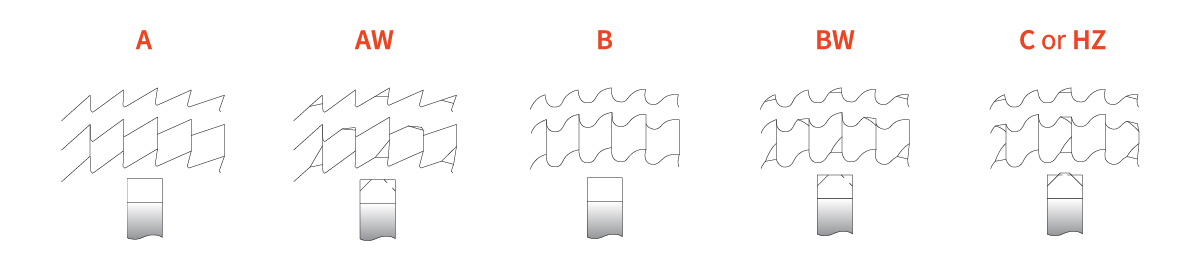

The common tooth profiles in use in New Zealand are:

A

All teeth square-ground with a small-radius gullet and straight back, rake up to 20° or more.

Use for short-chip, non-ferrous materials (brass, bronze, etc.)

AW

Tooth form generally as for ‘A’ but has alternate sides ground.

Helps to centre the blade and break chips, materials as for ‘A’ type.

B

All teeth ground square with a curved back and well-rounded gullets, rake from 10 to 22°.

Best used for this blades cutting thin-walled pipe & profiles.

BW

Tooth form generally as for ‘B’ but has alternate sides ground.

A good general-purpose option for mild steel, also good for aluminium and copper when used with a coarse pitch.

C or HZ

‘B’ – style tooth form but teeth alternate between a full ‘B’ style and a ‘triple chip’ profile that is 0.1 to 0.2mm higher than the preceding tooth.

Best for aluminum and solids, with higher cutting power than a ‘BW’ blade but also noisier and leaves a less clean finish.

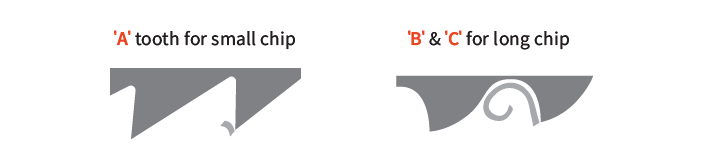

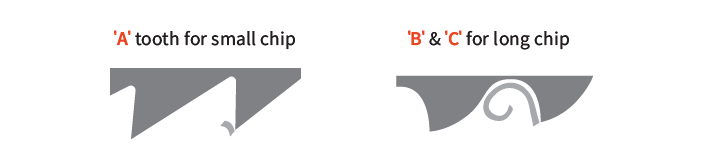

Remember that ‘A’ & ‘AW’ have small gullets so work best with small-chip materials, ‘B’ or ‘C’ style teeth have larger, rounded gullets and are for long-chip materials.

Tooth pitch selection

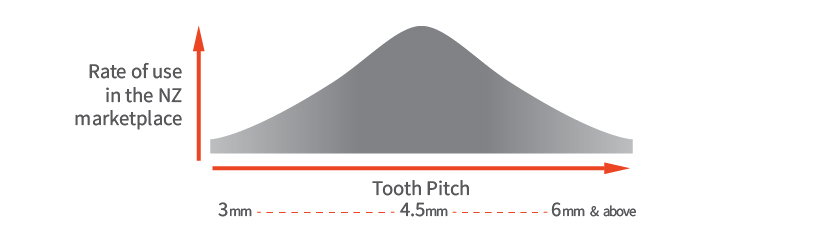

Picking the ideal tooth pitch depends on several factors, but it’s best to keep in mind some basic guidance:

Taking mild steel as a basis, an average of 2-6 teeth in the cut is a good rule of thumb to aim for. Solid materials will typically have 5-6 teeth engaged, while non-solid materials will be at the other end of the scale. Remember when cutting non-solid materials, the average tooth count will need to factor in both the thin side walls and the wider bottom.

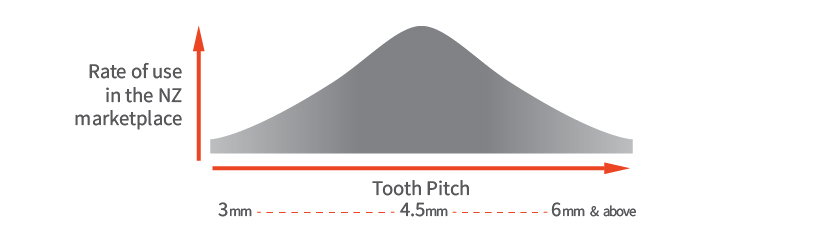

These are guidelines only, and better results can sometimes be achieved with different settings. In NZ, the most commonly used pitch for coldsaws, and a good starting point for when it’s tricky to determine the ‘correct’ pitch, is around 4.5mm. Bear in mind though that thin-walled tube, brass, copper and aluminium will almost certainly benefit from having fewer teeth in the cut and using a higher blade speed.

Suggested running speeds

The following recommendations are not intended to give a complex, formula-based equation for any possible combination of blade and material, rather they provide a rule-of-thumb guide to selecting the speed for most typical applications on the type of machinery usually operated by NZ users. We’re going to assume that the majority of machines in use have a two-speed setting, so the recommendations are given as HIGH or LOW ranges, allowing you to pick your machine’s setting that best matches the material.

| MATERIAL | 200 to 250mm diameter blades |

| Mild steel | HIGH |

| Medium hard steel | LOW TO HIGH depending on hardness, hard= LOW |

| Stainless steel | LOW |

| Aluminium (& Plastics) | HIGH (can be as high as 1000rpm + if available) |

| Copper | HIGH (can be as high as 330rpm + if available) |

| Brass | HIGH (can be as high as 450rpm + if available) |

Summary

Coldsaws are technical tools made really simple, but they still need some TLC to get the best from them. We sharpen so many coldsaw blades it’s hard to count, but every one tells the story of how it ended up blunt or damaged and many of them could have been avoided. Always keep them cool, try to use appropriate pitch and tooth profiles for the work material and keep an eye out for the clues that they’re not happy.

Oh, and avoid using them for cutting angle iron, they really don’t like it!