This information will help you to select the best geometry and grade/coating combination for your requirements from our standard ranges of turning inserts. It is intended as a basic guide to assist in selecting inserts. The specifics of other factors, e.g. workpiece, process, etc. should be considered and may affect the determination of the 'ideal' insert for the job at hand.

Note that many other geometries and grades are available, and we are generally able to source specific combinations where necessary, but to make your selection process as straightforward as possible we've limited the standard ranges to a manageable choice of alternatives that meet the majority of NZ industry demands.

As standard, we carry two Widia ranges, VariTurn and Victory. VariTurn is our recommended range for general & conventional turning, and Victory for high-speed and CNC machines. Grades for other turning inserts, e.g. threading, are also shown.

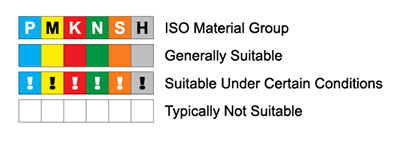

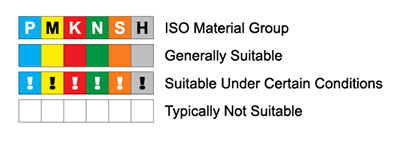

Material suitability of the various grades is shown as:

Grades

THM (Victory): For demanding conditions in cast iron and all non-ferrous metals and non-metals.

TN20K (VariTurn): Ideal for straight or lightly interrupted cut applications in ductile and cast irons (K).

TN15M (VariTurn): General-purpose machining of stainless steels (M) with good wear resistance.

TN30M (VariTurn): Roughing & general-purpose machining of stainless steels (M), with good

toughness property.

TN10P (VariTurn): Ideal for light finishing to medium machining applications, with superior

wear resistance.

TN20P (VariTurn): General-purpose turning grade for steels (P).

TN30P (VariTurn): Tough carbide grade, ideal for roughing & heavy roughing applications.

TN10U (VariTurn): Ideal for finishing of difficult to machine alloys and stainless steel (M).

TN15U (VariTurn): Excellent abrasion resistance for machining cast irons (K), austentic stainless steels and most high-temp alloys (S).

TN6025 (Threading): General purpose grade for threading in most materials.

TTR (Victory): Uncoated carbide, ideal for light and medium machining of Steel at low cutting speeds and in unfavourable conditions.

WK05CT to WK20CT (Victory): First choice for demanding applications in cast iron (K). Speeds decrease as cut severity and grade value increases.

WM15CT to WM35CT (Victory): For stainless steels (M) and high temp alloys (S). Speeds decrease as cut severity and grade value increases.

WP15CT to WP35CT (Victory): For steels (P), free-machining through to high tensile types. Speeds

decrease as cut severity and grade value increases.

WS10PT (Victory): Has an advanced multi-layered PVD coating. Can be used on a variety of materials and with a wide range of speeds & feeds.

WS25PT (Victory): For demanding applications in most steels (P) and stainless steels (M), high-temp

alloys, titanium & non-ferrous. Interrupted machining & high feed-rates attainable.

WU10HT (Victory): For finishing to medium in non-ferrous (N), also steel (P), stainless steels (M) and

high-temp alloys.

WU05PT (Victory): Ideal for aluminium and non-ferrous (N) and suitable for continuous cuts in steels (P),

stainless steels (M) and high-temp alloys (S).

WU10PT (Victory): Ideal for finishing to general machining of most workpiece materials at higher speeds.

Excellent for most steels (P), stainless steels(M), cast irons (K) and super alloys under stable conditions.

WU25PT (Victory): Ultra-fine grade substrate for general purpose machining of most steels (P), stainless

steels (M), high-temp alloys (S) and cast irons (K).

Geometries & Chipbreakers

1P (VariTurn): Positive inserts for finishing work.

2P (VariTurn): Negative inserts for finishing work.

4P (VariTurn): Negative inserts for medium work.

6P (VariTurn): Negative inserts for roughing work.

AL (Victory): Aluminium. Extremely sharp edges for low cutting forces and short chips in aluminium, non-ferrous metals and plastics.

FF (Victory): Fine Finishing. For finish turning, producing smooth, accurate surfaces. Very good chip control, especially at low depths of cut.

FP (Victory): Finishing Positive. For finishing to medium turning operations with optimal chip control over a wide range of cutting conditions and workpiece materials.

M0 (VariTurn & Victory): Universal geometry generally suitable across most applications.

ML (Victory): Medium Machining. For finishing to medium machining with a negative, stable cutting edge.

MM (Victory): For medium machining of most materials.

MP (Victory): Medium Positive. For medium to rough turning with reduced cutting forces and improved chip control for high feed rates. Suitable for high metal removal rates and spindling applications.

MR (Victory): Medium Roughing. For medium to light roughing of steels, difficult-to-machine high-alloy titanium, and aluminium materials. High strength to deal with heavy chip deformation.

MS (Victory): Medium High Temp (S). For medium machining in high-temp materials. Utilizes a micro-finished edge preparation to increase edge toughness.

MU (Victory): Medium Universal. A medium universal geometry with a soft cutting action due to its positive geometry. Has a versatile application range and is suited for turning unstable components and for boring applications.

RH (Victory): Heavy Roughing. For medium-duty to roughing. Outstanding chip control. High edge strength for interrupted cuts, forging skin, or scale. Preferred for all cast iron such as grey, malleable, and nodular.

UF (Victory): Finishing with a positive edge for reduced cutting forces and superior finish quality.

UM (Victory): Universal Medium. For medium-duty turning operations. Soft-cutting chipbreaker. Used in applications producing varying chip sections, such as profile or copy turning. Good dimensional accuracy. For soft steel materials and outstanding for stainless steels.

UR (Victory): Universal Roughing. Roughing geometry with smooth chip forming and improved coolant flow for increased tool life. Positive geometry reduces cutting forces and improves depth-of-cut notching resistance. Ideally suitable for stainless steel applications and for smooth machining of steel.

[blank] (VariTurn & Victory): Universal geometry generally suitable across most applications.

The grades & geometries indicated in these tables are intended as a starting point only. Varying steel compositions & machinery employed will affect the final best choice. We encourage the machinist to experiment in order to obtain the best insert type to suit the material & machinery combination.